- 03 products

- Filtration

- Perfiltra® & Harbolite®

- Celite®, Diactiv®, Kenite®

products

Celite®Diactiv®Kenite® filtration - Applications

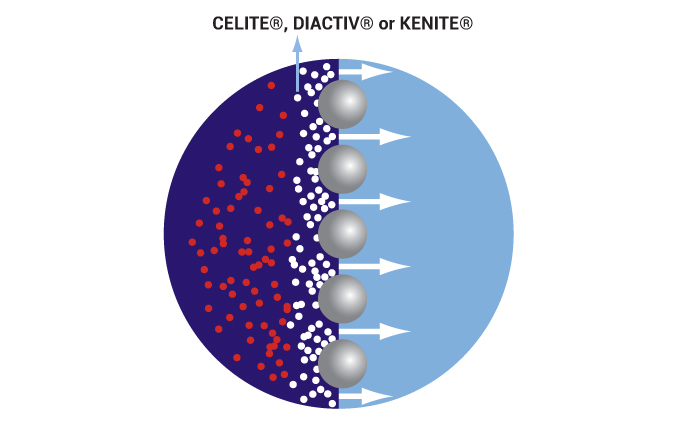

PRELAYER FORMATION

CELITE®, DIACTIV® and KENITE® are applied as a layer in the suspended filter cake, and the joint action with the filter cake achieves optimum filtration performance.

For a 1.5 to 3 mm width (pressure filter), from 200 to 500 gr of CELITE®, DIACTIV® and KENITE® are required per square meter of filtering area.

The best flow speed during prelayer formation ranges between 40 to 60 liters per minute, per square meter of filtering area (water filtration).

Prelayers ranging from between 50 mm and 100 mm are used in rotatory filters.

The suspended amount of CELITE®, DIACTIV® and KENITE® pumped in the filter varies between 2% and 6% of the weight of the substance to be filtered.

DISPENSING

Adding CELITE®, DIACTIV® or KENITE® to a liquid before being sent to the filter is known as dispensing.

The amount to be dispensed depends on each application, and ranges between 0.1 to 1% of the weight in suspension, being capable of reaching up to 8% in the case of solids having more difficult filtration (colloids, compressible solids, etc.).

Dispensing of CELITE®, DIACTIV® or KENITE® may be added directly to the liquid tank to be filtered or added in dosages to the suspension tank in the admission filter..